Perfect Paint Brush Filaments

Smooth, Durable & Efficient

What Paint Brush Users Truly Need

Smooth & Streak-Free Application

Tapered polyester filaments ensure even paint distribution and leveling for a flawless finish.

Superior Paint Load & Release

Hollow PET filaments maximize paint retention while allowing controlled transfer to surfaces.

Chemical & Solvent Resistance

High-quality materials withstand harsh chemicals in oil/alkyd-based paints without degradation.

Durable & Long-Lasting

Engineered filaments maintain elasticity and form after repeated use and cleaning.

Problems Caused by Low-Quality Filaments

Streaks & Brush Marks

Poorly finished filaments create uneven paint distribution and visible application marks.

Shedding & Linting

Weak filaments break off during use, embedding in paint surfaces and ruining finishes.

Premature Wear & Deformation

Low-grade materials lose shape quickly, reducing brush effectiveness and lifespan.

Paint Dripping & Poor Control

Inconsistent filament design causes messy application and wasted material.

BrushMake Filaments Solve It All

Premium Materials

100% high-grade Tapered Polyester Filament, Bristle Mixed Filament, Hollow PET Filament, chemical-resistant for professional oil & solvent-based paints.

Tailored for Performance

Custom diameter, length, and stiffness for any brush design.

Trusted by Global Brands

OEM/ODM support with strict QC standards.

Choose the Right Filament for Superior Paint Brushes

Tailored Materials for Optimal Paint Application & Brush Durability

Smooth Painting & Even Coating

Recommended Material:

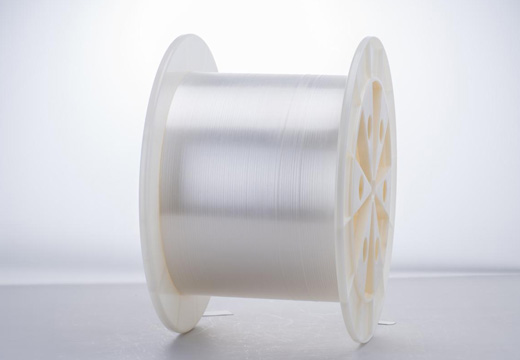

Tapered Polyester Filaments

Key Features:

Fine and flexible bristles ensure smooth paint application without streaks, excellent paint retention for even coverage, resistant to common solvents and wear.

Ideal for:

High-precision painting brushes, varnish brushes, furniture coating brushes

Tech Specs:

- Diameter range:

- 0.15mm – 0.25mm

- Stiffness:

- Soft to Medium (50–60 Shore D)

- Solvent resistance:

- Excellent

Durability & Heavy-Duty Performance

Recommended Material:

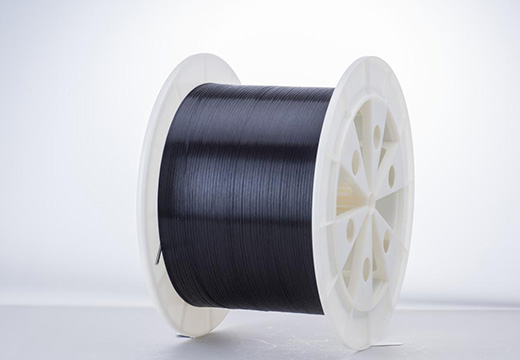

Bristle Mixed Filament

Key Features:

High rigidity and resilience for heavy-duty applications, maintains shape under prolonged use, compatible with oil-based and latex paints, easy to clean.

Ideal for:

Wall painting brushes, exterior paint brushes, industrial coating brushes

Tech Specs:

- Diameter range:

- 0.15mm-0.25mm

- Stiffness:

- Medium to Firm (60–70 Shore D)

- Heat resistance:

- Up to 120°C

Lightweight & Efficient Paint Pickup

Recommended Material:

Hollow PET Filament

Key Features:

Lightweight bristles with high paint absorption and reduced splatter, ideal for smooth and controlled application, quick cleanup and compatibility with water-based paints.

Ideal for:

DIY home painting brushes, ceiling brushes, interior decor brushes

Tech Specs:

- Diameter range:

- 0.15mm - 0.25mm

- Stiffness:

- Medium (55–65 Shore D)

- Paint absorption:

- High

Custom Designs & Unique Configurations

Our Custom Solutions:

Any diameter from 0.08mm (micro-detail) to 0.25mm (heavy coverage)

Specialty shapes:

Angled, curved, tapered, notched

Color-matched filaments for brand identity

Proprietary blends for specific viscosity requirements

Complete OEM support from prototype to mass production

Tech Specs:

- MOQ:

- As low as 250KGS

- Lead time:

- Samples in 7 days, production in 15-30 days

- Certifications:

- REACH, FDA, ISO 9001 compliant

Why BrushMake Stands Out

15+ Years of synthetic filament expertise

In-house R&D lab for material innovation

Global logistics with warehouses in US/EU/Asia

Premium Filaments for Every Nail Brush Need

Match the Perfect Material to Your Brush Design

Tapered Polyester Filament

Ideal for flawless, streak-free surfaces

- Superior Flow and Finish – Engineered for a smooth, streak-free application.

- Chemical Resistance and Easy Maintenance – Withstands harsh solvents and cleans easily with minimal paint buildup.

Best For: Fine woodworking, varnish, trim, and precision detailing.

Brush Types: High-end angled brushes, trim brushes, cabinet brushes.

Bristle Mixed Filament

Balanced performance for universal applications

- The Ultimate Control & Finish – Achieve professional results with a brush designed for perfect paint pickup and smooth application.

- Unmatched Versatility & Value – A resilient, long-lasting tool trusted by DIYers and pros for all paint types and projects.

Best For: General wall painting, furniture refurbishment, DIY projects.

Brush Types: All-purpose wall brushes, flat brushes, synthetic blend brushes.

Hollow PET Filament

Engineered for maximum paint retention and reduced weight

- Reduced Fatigue, Increased Capacity – The hollow ergonomic design is exceptionally lightweight and holds more paint to minimize reloading and strain.

- Superior Control & Coverage – Delivers consistent, predictable paint flow for a smooth finish and maximum coverage per dip.

Best For: Large surface coverage, exterior painting, heavy viscosity paints.

Brush Types: Exterior house brushes, masonry brushes, heavy-duty paste brushes.

Technology Comparison Table

PA 612 Filament

Parameter

| Diameter Range | Chemical ResistanceAcetone Immersion | Heat Deflection Tempat 0.45MPa | Optimal Viscosityat 0.45MPa |

| 0.05-0.25mm | 100 cycles | 80°C | Low-Medium50-500cP |

PBT Filament

Parameter

| Diameter Range | Chemical ResistanceAcetone Immersion | Heat Deflection Tempat 0.45MPa | Optimal Viscosityat 0.45MPa |

| 0.05-0.25mm | 500+ cycles | 150°C | High1000-3000cP |

PBT Tapered Filament

Parameter

| Diameter Range | Chemical ResistanceAcetone Immersion | Heat Deflection Tempat 0.45MPa | Optimal Viscosityat 0.45MPa |

| 0.05-0.25mm | 500+ cycles | 150°C | Ultra-Precision<100cP for detailing |

Recommended Products

- Precision application control

- Long-term durability

- Chemical/heat resistance

| Filament Name | Properties | Colors Available | Special Treatment | Compatible Equipment Models |

|---|---|---|---|---|

| PA612 Nylon Filament | Soft, wear-resistant, fine texture,ideal for precise application | White, Clear | No | Automatic implant machines (e.g. XYZ-100o), Manual fixing machines |

| PBT Filament | Excellent elasticity, medium stiffness, heat-resistant, high stability | Clear, Black | No | Automatic implant machines (e.g.ABC-500) |

| Wool Filament | Ultra-soft,excellent tactile feel,perfect for delicate work | White, Cream | No | High-speed brushing equipment(e.g. HDP200O) |

| PES (Polyester) Filament | High stiffness, strong elasticity,abrasion-resistant, UV-resistant | Multi-color (Blue, Red etc.) | No | Manual implant machines (e.g.MT-300) |

| Synthetic Fiber | Heat-resistant, chemically stable, | Black, White | Anti-static treatment | Automatic implant machines |

| Filament | corrosion-resistant | (e.g. CMP-100) |

Nail Brush Filament Handling Guidelines for Manufacturers

Filament Mixing & Uniformity

Ensure Consistent Quality

- Mix filaments thoroughly to guarantee uniform material and length

- Inconsistent mixing leads to unstable brush performance

Filament Anchoring & Insertion

Secure Without Damage

- Avoid over-compression when fixing filaments to brush handles

- Ensure each filament is firmly anchored to prevent shedding

Moisture Control & Storage

Maintain Material Stability

- Store in cool, dry areas away from sunlight and high humidity

- Prevent deformation and moisture absorption

Equipment Maintenance

Regular Upkeep for Optimal Performance

- Routinely inspect and clean production equipment

- Prevent contamination and ensure consistent quality

Need tailored support for your production line?

Physical Properties for Paint Brush Filaments

| Parameter | Density | Melting Point | Water Absorption |

| Tapered Polyester Filament | 1.31g/cm³ | 210℃ | 0.30% |

| Bristle Mixed Filament | 1.25 - 1.40 g/cm³ | 150℃ | 1% - 20% |

| Hollow PET Filament | 0.80 - 1.35 g/cm³ | 210℃ | 0.30% |

Crafted for Excellence, Empowering Superior Production

International-Standard Quality

- FDA/REACH certified raw materials

- 100% batch inspection with laser micrometer (±0.01mm tolerance)

- 36 laboratory-tested performance indicators

- 98.7% customer repurchase rate

Exclusive Customization Solutions

- Support for diameters ranging from 0.05-0.3mm

- Adjustable hardness range (Shore D 50-80)

- Pantone color matching service

- 300+ customized solutions developed

End-to-End Technical Support

- Free process parameter adjustments

- 48-hour emergency issue response

- Annual maintenance planning

- Average 35% improvement in production efficiency

Get a Quick Quote for Nail Polish Brush Filaments!

Fast, customized pricing tailored to your needs.

- Quick Quotation

- *Name

- *Mobile Phone

FAQ-Nail Polish Brush Filaments

- What are the advantages of PE over other polymers for food-grade brushing applications?PE is inherently inert, resistant to moisture and cleaning chemicals, and remains flexible in cold water, making it ideal for food processing.

- Is your PE filament certified as food-safe for direct contact with produce?Yes, our PE filament is compliant with strict international food contact regulations like FDA and EU 10/2011, ensuring absolute safety.

- How does PBT ensure gentle yet effective cleaning of delicate solar panel surfaces?PBT filaments are non-abrasive and can be engineered to the perfect stiffness for removing dust without scratching the glass.

Need Assistance?

We understand that choosing the right product for your industry is critical. That’s why we invite you to contact us. Whatever your goals, BrushMake will help you achieve them.

Learn MoreDo You Need Innovative Solutions?

We have a strong team that works closely with customers to meet market challenges and effectively meet specific needs. Our slogan is "Economical, Time-Saving, and Effortless Management" to help you gain the trust of customers in the industry.

Start Customizing