Begin your paint brush production journey with our full-spectrum assistance.

Customer Requirements and Material Selection

Customer Needs Analysis

We will communicate closely with you to gain a deep understanding of your production capacity requirements, cost control and quality standards to ensure the most suitable solution for your customization.

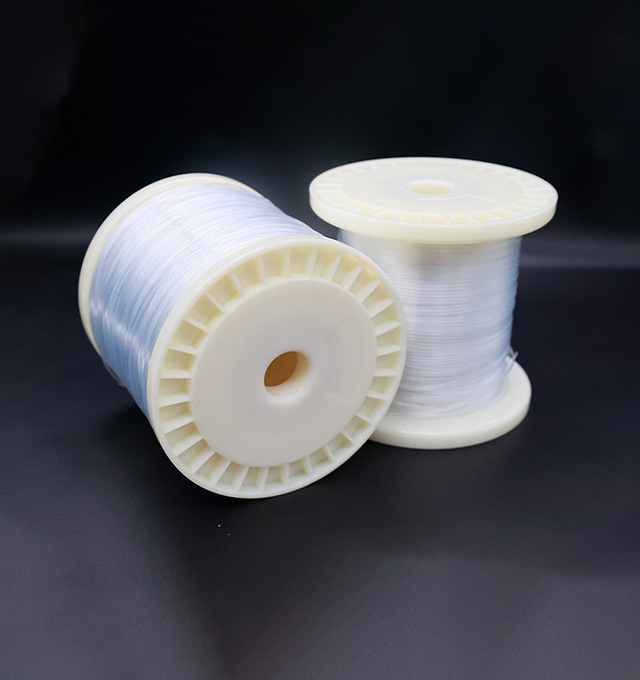

Material Selection and Requirements

We offer a variety of high-quality brush filament materials, including nylon filaments, synthetic fibers, and natural bristles. Based on your requirements, we select the most suitable material to ensure optimal performance and quality of the product.

Paint Brush Production Solution

Equipment Support

We provide a complete production equipment solution for paint brushes, from brush head forming to finishing. Our professional machinery covers core processes including precision tufting, brush head shaping, secure fastening, and surface finishing, ensuring every produced paint brush features high-quality characteristics such as a neat shape, secure filaments, and excellent handling. This meets the needs of different scales and production paces.

Equipment List

Tufting Machine

Provides efficient automatic or semi-automatic tufting equipment that precisely implants filaments (e.g., boar bristle, nylon) into the pre-drilled holes of wooden or plastic handles, supporting various tufting patterns and densities.

Trimming Machine

Used for trimming and shaping the tufted filaments to create various ergonomic brush head shapes such as flat, angled, and round.

Fastening Equipment

Provides automatic staplers, stamping equipment, or epoxy dispensing machines to securely fix the metal ferrule to the handle and permanently encapsulate the filament tuft within, preventing shedding.

Materials and Components

We supply all core materials and components required for manufacturing high-quality paint brushes. From a variety of natural and synthetic filament materials, durable handles and ferrules, to high-performance adhesives, we ensure all materials are strictly selected to guarantee exceptional painting performance, solvent resistance, and long service life of the final product.

Customer Requirements and Material Selection

Automation Production Support

We provide fully automatic production equipment to help you significantly reduce labor costs, minimize material waste, and improve production efficiency.

Customized Solutions

Based on the customer's production line layout and requirements, we offer customized equipment and production process optimization services to ensure flexible and efficient production.

Quality and Process Control

Improving Brush Quality

We ensure your paint brush products deliver exceptional painting performance and durability through professional equipment and premium materials. We optimize filament distribution uniformity and anchoring strength, achieving smooth and refined painting results while guaranteeing long-term shedding resistance, helping your brand earn the trust and recognition of professional users.

Cost Management

We help you optimize production processes and precisely control costs. By improving efficiency and reducing waste, we lower production costs while ensuring quality.

After-Sales and Technical Support

Technical Maintenance and Support

We provide comprehensive after-sales support, including equipment maintenance, spare parts supply, and operator training, to ensure your production line remains in optimal condition.

Continuous Optimization Solutions

Based on market changes and customer feedback, we continuously optimize solutions to ensure that our clients remain at the forefront of the industry.

Why Choose Our Paint Brush Solutions

Professionalism and Experience

With decades of professional experience in paint brush manufacturing, we have a deep understanding of the technical requirements of different painting scenarios. We provide professional-level production technical support to global clients, from filament selection to production process optimization, helping to enhance product performance and user experience, ensuring that paint brushes deliver excellent painting results and durability in various coating applications.

Unique Solutions

We not only provide high-quality filaments and advanced production equipment, but are also committed to offering complete customized solutions for paint brushes. From filament material selection to ergonomic handle design, from ferrule fixation process to finished product quality inspection, we ensure that every paint brush meets specific construction requirements, helping clients enhance product competitiveness and gain differentiated advantages in the professional coating tools market.

Your Strategic Partner in Brush Manufacturing, Driving Success Through Customized Solutions.

- Free Design

- Get Samples

- Overall Application Solution

- Free Quotation

Get a Quick Solution

- Quick Quotation

- *Name

- *Mobile Phone

Need Assistance?

We understand that choosing the right product for your industry is critical. That’s why we invite you to contact us. Whatever your goals, BrushMake will help you achieve them.

Learn MoreDo You Need Innovative Solutions?

We have a strong team that works closely with customers to meet market challenges and effectively meet specific needs. Our slogan is "Economical, Time-Saving, and Effortless Management" to help you gain the trust of customers in the industry.

Start Customizing