Begin your twisted brush production journey with our full-spectrum assistance.

Customer Requirements and Material Selection

Customer Needs Analysis

We will communicate closely with you to gain a deep understanding of your production capacity requirements, cost control and quality standards to ensure the most suitable solution for your customization.

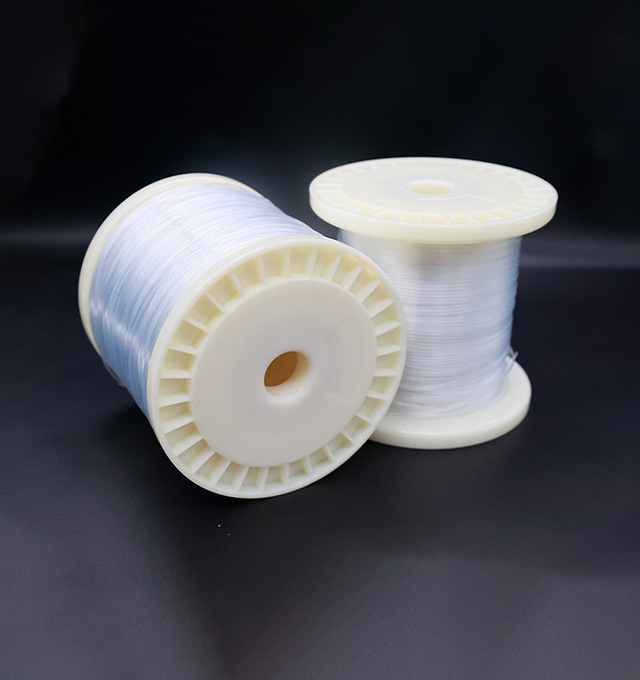

Material Selection and Requirements

We offer a variety of high-quality brush filament materials, including nylon filaments, synthetic fibers, and natural bristles. Based on your requirements, we select the most suitable material to ensure optimal performance and quality of the product.

Twisted Brush Production Solutions

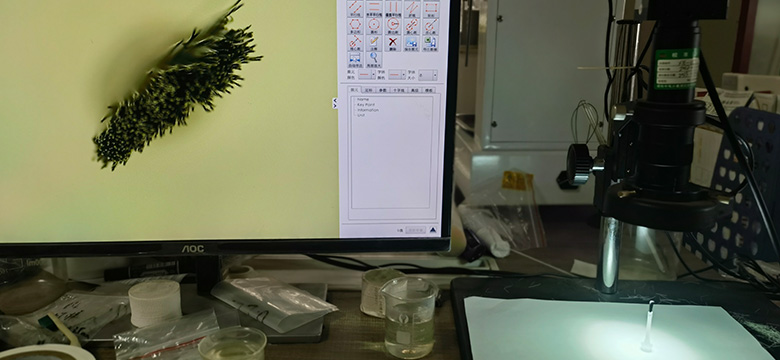

Equipment Support

We provide professional manufacturing equipment for twisted wire brushes, covering the entire process from precision filament cutting to efficient wire twisting and forming. Our filament cutting machines and versatile twisting machines are designed for various applications, enabling stable and efficient production of industrial-grade heavy-duty barrel brushes, delicate eyelash brushes, and high-standard medical brushes.

Equipment List

Twisting Machine

Provides a series of twisting equipment, supporting different twisting processes for single, double, or even multiple strands of wire. Capable of efficiently producing various forms of twisted wire brushes such as tube brushes, cup brushes, wheel brushes, and strip brushes, and is also adapted for the production of precision products like eyelash brushes and medical brushes.

Filament Cutting Machine

Provides high-precision CNC cutting equipment specifically for accurately cutting metal wires (e.g., stainless steel wire, brass wire) to predetermined lengths, ensuring consistent filament length, high precision, and clean cuts after twisting.

Filament Cutting and Precision Grinding Machine

Provides high-precision filament cutting and tip grinding equipment.

Materials and Components

We specialize in supplying the core material for twisted wire brushes—metal wires in various specifications and materials. All wires possess excellent elasticity, wear resistance, and corrosion resistance. We can provide the most suitable material options based on different application scenarios (e.g., metal surface treatment, medical device cleaning, personal cosmetics) to ensure the brush's performance and lifespan.

Customer Requirements and Material Selection

Automation Production Support

We provide fully automatic production equipment to help you significantly reduce labor costs, minimize material waste, and improve production efficiency.

Customized Solutions

Based on the customer's production line layout and requirements, we offer customized equipment and production process optimization services to ensure flexible and efficient production.

Quality and Process Control

Improving Brush Quality

We ensure your twisted wire brush products deliver exceptional industrial-grade performance through precision equipment and special materials. We optimize wire twisting accuracy and filament distribution uniformity, enhancing cleaning efficiency while guaranteeing long-term structural integrity, helping your brand establish a professional and reliable technical image.

Cost Management

We help you optimize production processes and precisely control costs. By improving efficiency and reducing waste, we lower production costs while ensuring quality.

After-Sales and Technical Support

Technical Maintenance and Support

We provide comprehensive after-sales support, including equipment maintenance, spare parts supply, and operator training, to ensure your production line remains in optimal condition.

Continuous Optimization Solutions

Based on market changes and customer feedback, we continuously optimize solutions to ensure that our clients remain at the forefront of the industry.

Why Choose Our Twisted Brush Solutions

Professionalism and Experience

With over 16 years of professional experience in industrial brush manufacturing, we have a deep understanding of the stringent requirements of various industrial application scenarios. We provide global clients with professional technical support and production process optimization, helping to enhance product performance and service life, ensuring that twisted wire brushes maintain excellent performance even in extreme conditions such as high temperature and high corrosion.

Unique Solutions

We not only provide special metal wires and advanced production equipment, but are also committed to offering complete customized solutions for twisted wire brushes. From material selection to process design, from special shapes to performance optimization, we ensure that every twisted wire brush meets specific industrial application requirements, helping clients improve production efficiency, reduce overall costs, and gain advantages in the competitive market.

Your Strategic Partner in Brush Manufacturing, Driving Success Through Customized Solutions.

- Free Design

- Get Samples

- Overall Application Solution

- Free Quotation

Get a Quick Solution

- Quick Quotation

- *Name

- *Mobile Phone

Need Assistance?

We understand that choosing the right product for your industry is critical. That’s why we invite you to contact us. Whatever your goals, BrushMake will help you achieve them.

Learn MoreDo You Need Innovative Solutions?

We have a strong team that works closely with customers to meet market challenges and effectively meet specific needs. Our slogan is "Economical, Time-Saving, and Effortless Management" to help you gain the trust of customers in the industry.

Start Customizing